Choosing the right PCB manufacturer for your company is vital to successfully delivering your product to the market.

Right PCB Manufacturer

Conducting your own research and getting referrals from those in your industry is a great place to start, but knowing what questions to ask when interviewing potential candidates can help even more in the decision-making process.

Also See: 7 Best Walking Pad

Let’s dive into some key factors to consider when hiring a printed circuit board manufacturer.

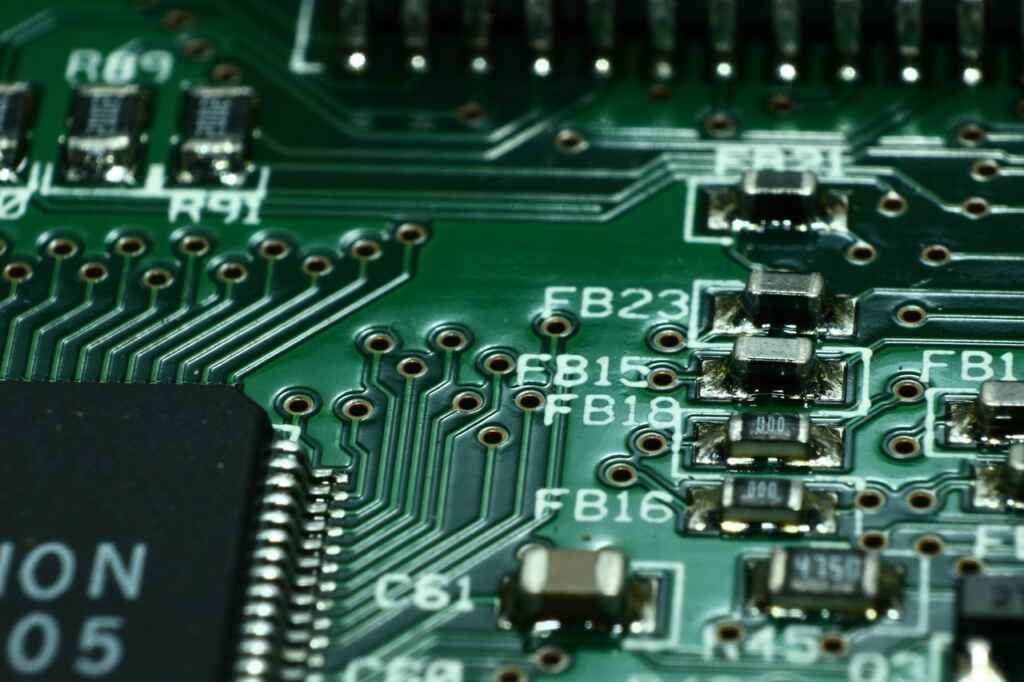

The Quality of the PCB

The quality of your PCB is of the utmost importance.

Delivering a low-quality product to your customers will land you in hot water. It can ruin business relationships, your reputation, and even invite costly lawsuits.

While you’ll want to keep your budget in mind, the quality of your PCB is not something that should be compromised.

Some top-level quality checks should include looking at board dimensions, checking that holes are accurately drilled and positioned, and ensuring there is minimal board warping.

Quality issues on a PCB board can not only ruin your reputation, but it can also put people in harm’s way. Remember when certain cell phones were … exploding? A faulty PCB could easily cause a similar issue. You don’t want to be behind a scandal like that.

Make Sure They Meet Your Requirements

Before moving forward with a PCB manufacturer, ensure that they can meet your requirements.

Send them your specs and ask if they can produce a product like this consistently. Ensure they accept the files you provide, can create the type of board you want (two-layer, flexible, multi-layer, etc.), and are familiar with the industry.

Whether you are submitting one order or plan to have recurring orders for them, the manufacturer should always be able to deliver.

PCB Manufacturing Costs

Not only is creating a product within budget necessary, but you should also try to reduce costs as well.

PCB pricing can vary depending on the board’s size, materials used, soldering required, and the timeline that needs to be met.

Remember that quality should come over cost, but when you find an experienced and reputable PCB manufacturer, they should marry both factors to meet your requirements.

Quality Control and Customer Support

Work with a manufacturer who takes responsibility for their work and quality.

Unfortunately, it’s common in the PCB world to have issues in production. Would you rather have a partner with lower quality control standards that lets a full batch of faulty products be loaded onto the truck? Or would you rather work with a manufacturer who checks their work throughout the process to keep things on track?

While it is the engineer or designer’s responsibility to provide PCB designs that work, no one is perfect.

Choosing a PCB manufacturing company that offers quality products, does its own testing, and has open communication with you are key factors for a successful working relationship.

A reliable manufacturer should be open to technical discussions, customer suggestions, and feedback. Asking the company for referrals and reading reviews will help you make a smart decision on what company to hire.

Choose a PCB Manufacturer That Fits Your Needs

Once you discover the requirements you need a PCB manufacturer to meet, it will be easier to dwindle down your options of who to hire.

Make sure to do thorough research on your prospects. Check for reviews, references, and ask associates in the industry. Choosing the right manufacturer is vital to bringing your products to market.