Aluminium is one of the most versatile metal elements around, and it is used in a wide variety of industries today. It makes such a good extruded metal due to its structural strength and ductility. That is why it makes up around half of the current extruded metal products market. And although it works just fine on its own, it is often combined with other metals to make alloys add even better attributes to the finished product.

In layman’s terms, aluminium extrusion is a process where an aluminium billet (a cylindrical bar of aluminium) is pushed through a steel die to create entirely accurate aluminium extrusion profiles in the desired shape, identical to the opening of the die through which it passes. The process can produce profiles with infinite shapes, from reasonably simple ones to incredibly complex cross-sections.

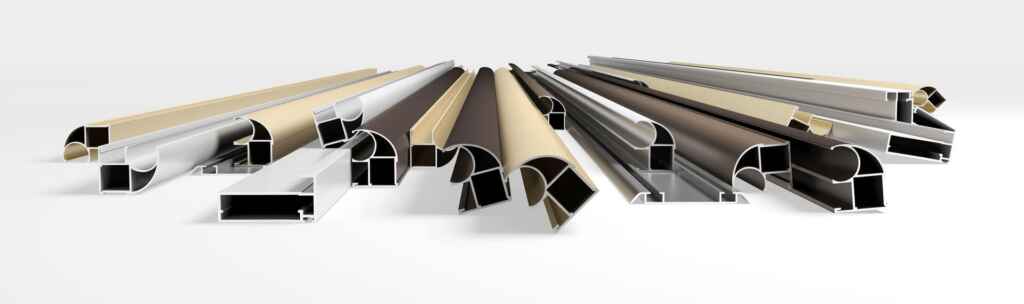

Photo from Alumil

It begins with the heating of the billet to 700-930 degrees Fahrenheit (depending on the alloy). The billet is then forced within the die using powerful hydraulic presses (varying from 100 to 15.000 tons). After the profiles come out from the other side of the die, they are quenched with water or air. Next, they are stretched, aged, cut, and anodized (to improve corrosion resistance), and that’s it!

Read along to find out the top advantages and benefits that this manufacturing technique puts on the table and its applications in various industries.

Top Benefits Of Aluminum Extrusion Profiles

Aluminum Extrusion Profiles Are Incredibly Lightweight

Aluminium is a prime choice in any motion-related application. It sits at about a third of the density of steel. Lightweight means less inertia, translated to higher speeds and energy savings. To add to this, the advantage of the extruded section is that it only places material where it is needed, potentially further reducing weight.

They Are Remarkably Strong

Compared to many other materials, aluminium has a higher strength-to-weight-ratio. 6061-T6 grade aluminium is nearly four times the strength of 304 stainless. Furthermore, extrusion maximizes stiffness while minimizing weight at the same time. That’s why it’s extensively used in building aircraft, which need to be as light as possible to get off the ground into the air while load-bearing.

Photo from Medium

No-Risk Of Corrosion

Aluminium rarely rusts. This is because rust is iron oxide, and most aluminium has virtually no iron in its composition. However, aluminium does oxidize, but it protects the underlying unoxidized aluminium.

The aluminium oxide is more corrosion repellent than the aluminium alloy it rests on. This is distinct from rust because rust will flake away from an iron alloy, allowing the rusting process to continue until material failure.

No Need For Welding

To be able to be good at welding consistently requires excellent skills and practice. Additionally, you’ll often need fixtures and may have to waste some pieces for training.

On the contrary, one specifically designed piece of extruded aluminium can replace multiple separate parts that would otherwise be welded together. You can even create sections that interlock to make everything smooth.

Aluminum Extrusions Are Easy To Work With And Come With Appealing Appearance

Machining can be done quickly on most grades of aluminium. Aluminium extrusions can be cut to length with a hacksaw or with a basic cordless hand drill. Be sure to mark the holes on your frame carefully!

You can plate, paint, polish, and even texture extruded aluminium. And of course, there’s anodizing that provides designers with a wide array of finishes to choose from. This isn’t possible with many other materials.

Offers The Option To Recycle And Reuse

Scrap aluminium is a significant market. This means when your product has reached the end of its life, you won’t have to worry about disposal. On the contrary, it does have some value. You can sell it but also reuse it differently. Just disassemble your product, and the extrusions could be suitable to be used again.

Relatively Cheap Tooling

People who intended to use extruded aluminium will often limit themselves to only the shapes available in catalogues of standard products. However, this can be a mistake. There are great opportunities for optimizing designs because tooling for custom extrusion is very reasonably priced.

Industrial Applications Of Aluminum Extrusion Profiles

Display Equipment

Practically every stand that you observe at an exhibition or a fair of any kind was made with extruded aluminium. It is because extruded sections can be designed, so pieces interlock. This makes assembly easy and super fast.

Photo from Medium

Due to its lightweight, it’s straightforward to move around and can be finished in many different ways to give a lovely appearance. It’s very durable, too.

Electrical Systems

Extruded aluminium is often used for busbars and other electrical equipment because of its good conducting properties. Lighting is another application. Nowadays, LED fixtures can be tough to manage.

Aluminium extruded with fins will make a great heat exchanger or radiator. It is easily mounted and coloured and isn’t bulky when mounted overhead. Another use is in the solar panel support structure. These require resistance to corrosion and strength, together with low mass, so aluminium extrusions are very suitable.

Construction And Architecture

From fences and railings to building facades and bleachers, aluminium is there. Because of its stiffness and lightweight, it is ideal for canopies where the structure mustn’t weigh much but has to handle a significant load. It’s also used for suspended ceilings and in walls.

Transportation

Weight is a crucial issue in transportation. The obvious example is aviation, but aluminium extrusions are also applied in automotive products like trailers, from 53’ semi-trailers to boat and horse trailers. Keeping trailer weight down means the towing vehicle will spend less torque on moving the trailer. RVs extensively feature aluminium extrusions because of their corrosion resistance and a decorative feature since it can be polished to resemble a lot like chrome.

Photo from RV Trader

Numerous Industrial Applications

It is almost guaranteed that you’ll see aluminium extrusions in every factory you’ll visit. Inspection tables and carts, workbenches are all primarily made with aluminium extrusions.

This is because it’s easy to drill and cut and it’s reasonably priced. Most importantly, it’s stiff and lightweight at the same time. Another great feature is extendability. Any desired modifications can be quickly and smoothly done.

Final Words

If you try to train your eye to look for metal fabrications, you’ll spot them everywhere. You’ll see many buildings and objects that were built using aluminium extrusion. It is the most extraordinarily versatile material, and that’s why experts like working with it.

If you’re questioning whether extruded aluminium might be the right choice in your next project, it probably is. Contact a specialized extrusion company or a supplier and get to work!